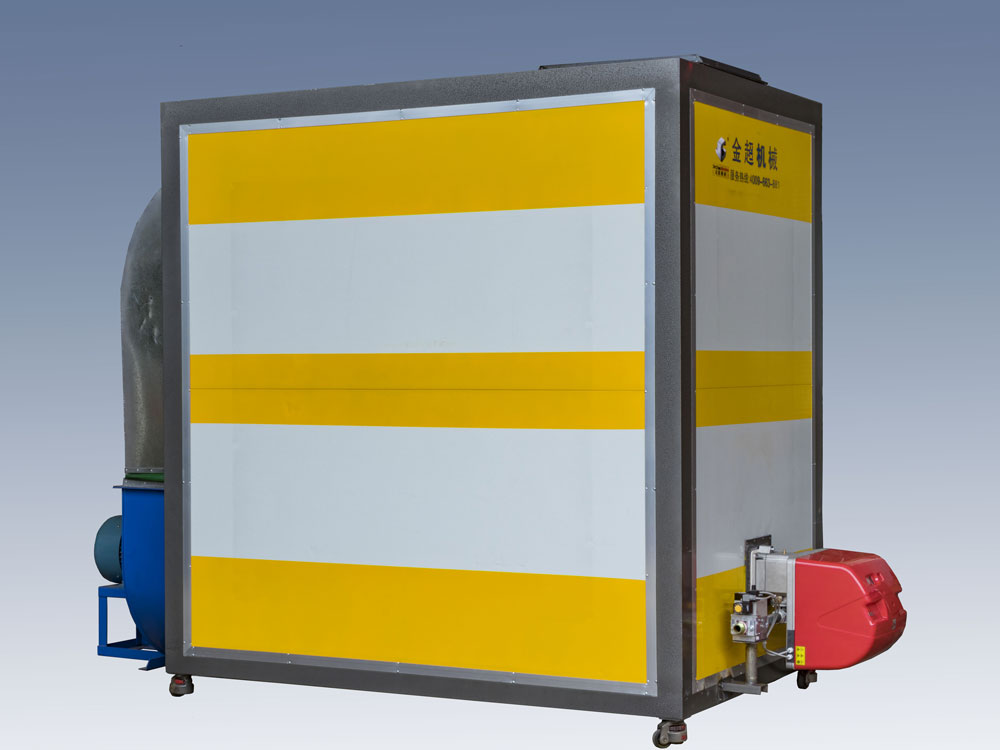

The square gas hot blast stove is designed and manufactured with integral structure and steel structure shell. The hot air stove integrates combustion and heat exchange, and uses the latest indirect heating technology to exchange heat with the high-temperature part of the furnace body. It has taken high-temperature resistance measures to make its service life several times as long as the traditional tubular hot air stove. The output hot air temperature can reach 300 ℃, and the special design output hot air temperature can reach 500 ℃~800 ℃. At the same time, the flue gas longitudinal washing radiator and negative pressure suction smoke exhaust method are adopted, and the heat exchange part is free of dust and need not be cleaned, Stable thermal performance.

1、 Operating characteristics of square gas-fired hot-blast stove:

1. When the burner of the square gas-fired hot-blast stove starts to operate, natural gas, liquefied gas, propane, butane and other gases are controlled by the microcomputer control system to enter the burner according to the program. The primary air and combustible gas are mixed, ignited and combusted, and the secondary air is combustion-supporting to achieve full combustion. The combustion status of the burner is detected and controlled by the automatic flame tracking system. When the burner has a fault (lack of oxygen in the combustion chamber, cut-off of combustible gas, insufficient gas volume, etc.), the control system sends a command, the solenoid valve of the gas supply system closes quickly, cuts off the gas supply path, and the burner automatically stops, indicating the fault.

2. Control of square gas-fired hot-blast stove: automatic control is adopted. The corresponding control temperature range can be input on the temperature controller according to the requirements, and the combustion system will operate automatically.

3. The combustion equipment has microcomputer programmed control, automatic ignition, automatic flame tracking, automatic flameout protection, two-stage combustion and proportional automatic regulation control.

2、 Technical advantages:

Fast drying speed - the oil burner is directly heated in the box, with large heat exchange area, fast heating speed and short heating time. 2. Fuel saving - due to the reasonable arrangement of heating surfaces, the fuel is fully combusted. The exhaust temperature is lower (130 ℃), and the thermal efficiency reaches 94%. The thermal utilization rate of this device is generally 90~92%.

3. Save investment - affordable, fuel fully burned.

4. Safety and environmental protection - Full-automatic air-blowing oil-fired burner for oil-fired hot blast stove has the following features: microcomputer programmed automatic control, proportional regulation, two-stage combustion, automatic ignition, automatic flame tracking, automatic shutdown protection for flameout. The water tank has no pressure, stable operation, safety and reliability, full combustion, no smoke, low nitrogen, and no pollution, meeting the environmental protection standards.

5. Automatic control - intelligent temperature control. After the desired temperature is set by yourself, it can realize the upper limit temperature shutdown or insulation state, lower limit startup or fire combustion. As long as there is electricity and gas (the gas source is stable), the system can be operated and operated automatically.